ERGONOMIC DESIGN

Human Factors Control Room Ergonomics & Desk

It’s the experience that we have earned over all these years, that helps us in planning the correct control room solutions for our customers. We have designed and engineered

Human Factors Control Room Ergonomics & Control Room Desk more than 150 Control Rooms in just 8 years. Our customers address us with the name “Control Room Guys”.

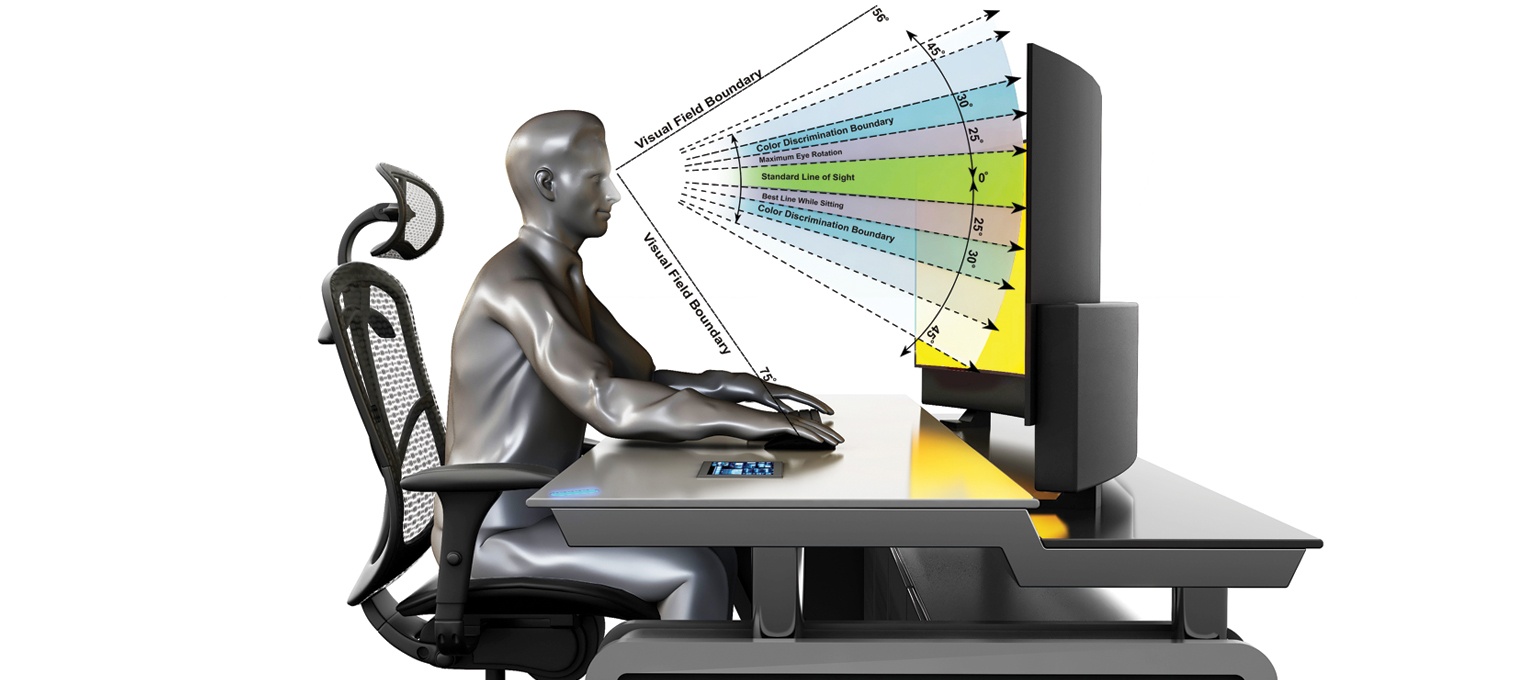

Our control room solution is directed towards catering the needs of its users. Every control room has different needs which are all governed by the human machine interface. We therefore take the human factors and ergonomics into consideration while planning a design of task specific control room.

The Human factors that we take into consideration while designing a control room are mostly inclined towards control room operators, their interaction with machines within the control room and the various functionalities of the control room environment, as the alertness and focus of the operators is what it takes in executing mission critical tasks of a control room.

HUMAN FACTOR ENGINEERING/ ERGONOMICS

Location of control room building with respect to the plant

Location of control room in the building Functionality defining the no of operators HFE incorporating ergonomics, viewing angles, lux levels, dynamic lighting, HVAC, fire & safety, traffic patterns, furniture design and overall aesthetics

Location of the building depends on the overall plant layout and definition of the primary source of information to the operator. And this defines the nature/form of building (normal/blast proof, windows/ blank walls, remote/plant vicinity)

Location of the control room in the building depends on the functionality and safety concerns in the building. It should facilitate the operators with easy egress in case of emergency and should allow a hassle free environment equipped with suitable paraphernalia and facilities in the vicinity. Its recommended that the control room should avoid canteen and noise creating areas in the vicinity.

Functionality and occupancy of the Control is derived out of a workshop with the stake holders of the project ie the end users, automation contractors and the consultants involved. The task analysis of the each operator , corresponding console and relation to video wall defines the space and the matrix, thereby giving form and boundaries to the space. For example a convex console would be suitable if the video wall is smaller than the overall console length and if vice-versa its concave, the first row of operators see the bottom of the video wall the second row sees the middle and the third row sees the top.

These factors govern the layout and general arrangement of the CCR.

CONTROL ROOM BUILDING LAYOUT

CONTROL ROOM BUILDING LAYOUT

Workflows:

Requirements/ inputs of all the stakeholders need to be incorporated at the concept stage for effective design. Workflow shall be divided in to the following major groups.

Physical infrastructure:

Integrated Control & safety System

Process Operation Units

Production Management Systems

Location & Structure:

The control room location is determined by non- HFE factors such as safety, wind direction, desired free space around the building, potential for expansion, emergency response and the number of plants that are to be controlled from the control room.

Generic points regarding structure design include:

· The structure should be suitable to withstand possible major hazards.

· It should be able to maintain plant control in emergencies

· It should have emergency exit at vantage points for safe evacuation, in case of emergency.

· With respect to building access, account should be taken of equipment as well as all personnel. In practice, this means that it shall be possible to transport equipment easily through the building. Free passageways of at least 1200 mm should be provided.

·Other personnel and visitors should enter the control building not via the plant entrance, but via a separate entrance (main entrance) and the central corridor.

Floor Space Engineering:

The space allocation for control room is determined by:

· Space needed for the console configuration.

· Space for peripherals and other workplaces

· Space for large overview displays, if required

· Space for tiles

· Number of operators.

· Space for meetings

· Space for all support functions

· Space for administrative work, checking of drawings (‘manual table’), small meetings, etc.

· Space for utilities, administrative staff, false floored areas, visitors viewing areas to be allocated based on specific requirement of the control room.

ASPECTS OF DESIGN

ASPECTS OF DESIGN

Location of control room building with respect to the plant

Location of control room in the building Functionality defining the no of operators HFE incorporating ergonomics, viewing angles, lux levels, dynamic lighting, HVAC, fire & safety, traffic patterns, furniture design and overall aesthetics

Location of the building depends on the overall plant layout and definition of the primary source of information to the operator. And this defines the nature/form of building (normal/blast proof, windows/ blank walls, remote/plant vicinity)

Location of the control room in the building depends on the functionality and safety concerns in the building. It should facilitate the operators with easy egress in case of emergency and should allow a hassle free environment equipped with suitable paraphernalia and facilities in the vicinity. Its recommended that the control room should avoid canteen and noise creating areas in the vicinity.

Functionality and occupancy of the Control is derived out of a workshop with the stake holders of the project ie the end users, automation contractors and the consultants involved. The task analysis of the each operator , corresponding console and relation to video wall defines the space and the matrix, thereby giving form and boundaries to the space. For example a convex console would be suitable if the video wall is smaller than the overall console length and if vice-versa its concave, the first row of operators see the bottom of the video wall the second row sees the middle and the third row sees the top.

These factors govern the layout and general arrangement of the CCR.

ACOUSTICS

ACOUSTICS

A control room comprises of a task critical environment where most of the operations are job specific. The control room operators monitor and control the various activities of a specific system. The very task of monitoring requires concentration and focus , which could be hampered due to various sound disturbances. It’s not the material that defines acoustics, it’s the detailing which ensures controlled reverberations, resonances and reflections.

A noisy room can stimulate the occupants while a too quieter interior may be dull and un-inviting, therefore acoustic balance and control is of utmost importance in our control room designs. To offer a masking noise/ anti – noise solution to ensure privacy to the units, we take into consideration the various acoustic types, like architectural acoustics, aero-acoustics, environmental acoustics, psycho-acoustics, speech recognition/ synthesis and vibrations in and around the control room environment.

Recommendation as per Annex A, A.5/A.6, ISO 11064-6:2005(E):

- Ambient Noise: Less than 45 dB.

- Ceiling in Control Room: Acoustic Perforated Metal Grid False Ceiling

- Ceiling in Air Lock Room: Paint Finish

- Wall Paneling in Control Room and Air Lock Room: Insulated Sandwich Aluminum Panel

- Flooring in Control Room: Raised Flooring System consisting of metal pedestal base and head assemblies and inter-locking stringers with 600mm square panels having 1.5mm plastic lamination finish

- Flooring in Air Lock Room: 300mm x 300mm x 3mm Vinyl Tile

Technical Specification for Acoustic Environment:

- Acceptable noise level: Less than 45 dB

- Surface reflectance of floor finish: 0.2 to 0.3

- Surface reflectance of wall finish: 0.5 to 0.6

- Surface reflectance of glazed area: 0.5 to 0.6

- Surface reflectance of ceiling: Minimum 0.8

CONTROL AREA

CONTROL AREA

Control Section:

Control area location should be such that there is minimum disruption to operators. The shift supervisor’s room should be located in the immediate vicinity of the control room to facilitate the necessary functional and social contacts. The shift supervisor’s room should not be accessible solely via the control room because the associated comings and goings would disturb the operator’s concentration. Conference rooms should be provided in the control rooms for meeting, trainings etc.

Console Configuration:

- Account shall be taken of future expansion when determining the console configuration.

- The configuration of the plant layout consoles in the control room shall conform with the course of the process, from left to right. This is particularly important for the alarm displays.

- The consoles should be grouped functionally for each part of.

- Consoles shall be located so that there are no annoying reflections on the screen (the lighting plan should therefore always be drawn up after the console layout has been determined).

- Arrangement of the consoles next to one another, or at right-angles to one another in a U- shape or in a C-shape is dependent on the number of operators manning the console section and the functioning relationship between the various parts of the process Each of these arrangements has its specific pros & cons.

- Dual screens one above the other should not be used, as ergonomic studies have shown this arrangements to cause neck problems due constant straining of the head.

- The maximum number of actively used screens that an operator can physically operate in an upset situation is four next to one another( e.g. includes overview, detail and alarm annunciation screens). Screens for F&G & CCTV applications shall be provided adjacent to these screens. These factors, in conjunction with the number of operators needed in the control room, shall determine the console configuration.

- Console configuration should consider provision of equipment for all other systems communication devices such as PA system telephone as well as PC’s for other applications such as laboratory systems administrative use and advanced process applications.

- Console design shall ensure provision of stress-free work surface, optimum equipment placement for reach and view distances and sufficient leg clearance as per ergonomic norms.

MATERIAL & COLOUR

MATERIAL & COLOUR

- When choosing the materials, account shall be taken of their acoustic properties (e.g. density of rubber), light (disturbing reflections) and temperature (old to the touch).

- When selecting floor covering, account shall be taken of ease of moving office chairs past the consoles, ease of cleaning.

- Control room shall have wear resistant, acoustic floor tiles with non- reflective finish.

- Fairly inconspicuous color should be chosen, particularly for the large area (walls ceiling, etc.)

- The ceilings should be light-colored, the walls somewhat tinted, and the floor dark colored.

LIGHTING DESIGN/ ILLUMINATION

LIGHTING DESIGN/ ILLUMINATION

- A properly designed illumination plan adds life to the control room. Illumination also helps in enhancing the performance of the operators as well as to combat the fatigue and stress levels. We make LUX calculations to provide the correct spread of light arrangement inside the control room, where the intensity and reflectance parameters affect the operations of the operators.The illumination quotient is incorporated and maintained in our control room designs in such a way that it becomes a part of a soothing aesthetic surrounding. The intensity, the arrangement and the very color of lights inside a control room speak for the energy level of an individual present in the very control room environment. We maintain and distribute the most suitable arrangement of the Illumination Web in our control room designs.Based upon ergonomics, luminance levels of task areas should be within limitations so as to avoid excessive eye fatigue. Task areas are defined as areas that are to be viewed, while performing the subtasks in order to perform a certain task. These tasks are typical looking at workstation monitors, paper, and the display wall on-axis and off-axis. In order to ensure optimal task performance:

- The luminance level of the display wall will be similar to the luminance level of the other task area.

- In general, large luminance differences will be avoided. Luminance level are not too low and not to high.

- Luminance levels will also be in line with the overall luminance level of the surroundings (walls, ceilings, etc.)

- The average brightness of the display wall throughout the life of the lamp shall be 100 cd/m².

Readability & Contrast:

The readability is determined by the on-screen contrast. The on function of the following parameters:

- Projector contrast.

- Screen reflection.

- Ambient lighting and direction.

- Luminance level (a function of viewing angle).

- Sharpness of the pixels.

- Space Planning

TRAFFIC FLOW

TRAFFIC FLOW

- The mission critical environment of a control room requires a focused and an undperturbed concentration. Every movement of an individual operator can act like an element of distraction inside the control room design. The entrance, the exit of operators and their movement governed by their respective work style inside a control room are some of the factors which are needed to be planned and designed accordingly.We study the traffic flow practices in line with individual user specific needs and provide them with a detailed traffic flow management plan, to enhance the ease of operator movements and lessen the chances of any congested work practices in our control room designs.Our control room designs are unique, we do not repeat our designs and so there is a lot of research and development before we extend our control room design solution to the users. We design a complete control room experience meeting all the functional and technical requirements of a 24/7 mission critical control room environment. We keep on enhancing our designs by incorporating innovative aesthetic features to it, for giving a blend of focused work and work with comfort combination.

HUMAN FACTOR ENGINEERING/ ERGONOMICS

HUMAN FACTOR ENGINEERING/ ERGONOMICS

- Location of control room building with respect to the plantLocation of control room in the building Functionality defining the no of operators HFE incorporating ergonomics, viewing angles, lux levels, dynamic lighting, HVAC, fire & safety, traffic patterns, furniture design and overall aestheticsLocation of the building depends on the overall plant layout and definition of the primary source of information to the operator. And this defines the nature/form of building (normal/blast proof, windows/ blank walls, remote/plant vicinity)Location of the control room in the building depends on the functionality and safety concerns in the building. It should facilitate the operators with easy egress in case of emergency and should allow a hassle free environment equipped with suitable paraphernalia and facilities in the vicinity. Its recommended that the control room should avoid canteen and noise creating areas in the vicinity.Functionality and occupancy of the Control is derived out of a workshop with the stake holders of the project ie the end users, automation contractors and the consultants involved. The task analysis of the each operator , corresponding console and relation to video wall defines the space and the matrix, thereby giving form and boundaries to the space. For example a convex console would be suitable if the video wall is smaller than the overall console length and if vice-versa its concave, the first row of operators see the bottom of the video wall the second row sees the middle and the third row sees the top.These factors govern the layout and general arrangement of the CCR.